FINGER POINTING

All pressurized vessels must have a pressure relief valve or other safety device to prevent catastrophic failure of the vessel.

The relief valve should be tested regularly.

UC SANTA BARBARA

PRAXAIR WATCH

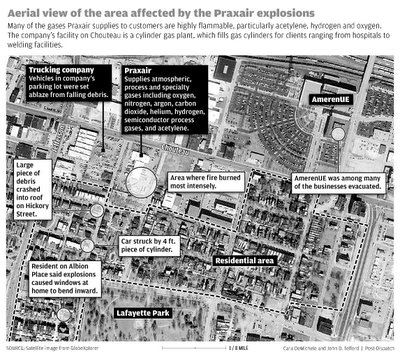

On September 29, 2005 - Praxair issues a press release & letter to Lafayette Square residents stating that: "They believe that a premature release of a safety relief valve on one or more gas cylinders containing flammable gas may have contributed to the St. Louis fire."

This sentence was structured to imply other forces are to blame for the conflagration and that Praxair, once again, is the victim. As in Bhopal, Praxair points the blame finger at someone else.

In this case....the cylinders cannot defend themselves.

I do not believe the device was premature. The device more than likely operated as it was designed to do.

I believe employee/management negligence is responsible for the incident.

A. one or more implies coincidence that several safety relief valves had erupted simultaneously.

B. premature implies the safety device manufacturer provided a sub-standard product.

PROPYLENE SAFETY DEVICE

During the fill process of any gas it is common practice to "*soap test" during charging period as well at the conclusion of a fill. I find it alarming that, nation wide, Praxair discovered hundreds of cylinders that were leaking at the safety relief device. Why are the employees not finding these "leaks" during or after the fill process? Neglect?

*soap test: as cylinders are filled pressure increases with-in the vessel. A simple soapy water test will reveal leaks by emitting "bubbles." (there is a "whoopie" factor in this test your employees will enjoy)

The Sherwood Valve Co. issued a safety notice asking their customers to adhere to the Compressed Gas Association guidelines (CGA S-1.1 paragraph 9.1.1) which recommends that valves be replaced after ten years due to weakening from many variables. I am curious as to how many of the 8,000 suspect cylinders Praxair pulled from service are not in compliance with CGA guidelines.

PRAXAIR WATCH

The Sherwood Valve Company also informs their customers that "good practice" includes shading cylinders from direct sunlight to reduce the effects of solar heating. Sherwood has also reminded their customers to avoid "over-filling" cylinders to avoid liquid expansion and vapor pressure associated with high temperatures and/or solar heating.

Why does Sherwood emphasize "solar heating" twice in the Safety Notice?

On the day of the explosions Praxair reports that the temperature on June 24, 2005 was about 100 degress. If these cylinders were not shaded as recommended, how "hot" to the touch did these metal cylinders get? Sherwood and the CGA have instructed customers to not allow temperatures where cylinders are stored to exceed 125 degrees F. With the combination of unobstructed sunlight and metal cylinders, what was the ambient temperature around and within these stored cylinders?

InterFire Fire Alert

Praxair has informed Sherwood of several unintended releases of propylene from 260 service pressure cylinders equipped with certain Sherwood PV3250A-405 and PV3250ALG-405 valves with pressure release device start-to-discharge settings of 405 psi. Praxair has also informed Sherwood that these releases have occurred at various locations in North America. Sherwoods investigation of Praxairs report is on-going. PRAXAIR WATCH

PRAXAIR admits "several" incidents "have occurred"!?

I'm curious. When do Praxairs moronic managers determine the need rectify potential hazards?

Praxair recalled 14,000 cylinders through-out North America for inspection. Praxair conducts business world-wide! Why do they find the Canadian and American public more valuable? Sherwood has recalled propylene valves with date codes from 1996 through 2004 that are suspect of leaking. Why did it take an explosion for this recall to take place? It is every employees responsibility to ensure the safety devices are in good condition. Why are they, industry wide, not conducting a simple soap test?

ACETYLENE SAFETY RELIEF DEVICE

1. Fusible plugs are hollow threaded studs filled w/lead. When cylinder is over-charged, lead plugs eventualy discharge slightly to allow pressure to release. These leaks are found with a simple soapy water test.

Was this routinely done?

2. If a cylinder is over charged with pressure, or if excessive heat is near the cylinder, plugs will completely dislodge so that cylinder will not explode. Pressure will jettison upwards emitting 3 - 5 ft of flame.

(In the event of fire, lead will melt and dislodge)

3. If cylinders are negligently over charged, safety devices will have no time to react and thermal decomposition will violently rupture the cylinder. ( for those of you at Praxair, this means go boom! )

BRITISH OXYGEN COMPANY MSDS

IT IS CRUCIAL THAT FUSE PLUGS IN THE TOPS AND BOTTOMS OF ALL ACETYLENE CYLINDERS BE THOROUGHLY INSPECTED WHENEVER HANDLED. REMOVE AND QUARANTINE IN A SAFE LOCATION ANY DEFECTIVE CYLINDER.

Protect cylinders from physical damage. Store in cool, dry, well-ventilated area away from heavily trafficked areas and emergency exits. DO NOT allow the temperature where cylinders are stored to exceed 125oF (52oC). Full and empty cylinders should be segregated.

I would recommend that the city review Department of Transportation records kept by Praxair. These records are documentation of cylinder pressure vs. temperature. i.e. @ 70 degrees cylinder pressure must not exceed 250 PSI. DOT requires that the facility keep these records for 30 days.

Since these documents are easily falsified, I would also suggest that during the Fire Departments annual inspection that they sample some of the full cylinders to verify that Praxair is operating within standard practice. Every acetylene plant must put into reserve cylinders from every completed fill process for inspection. They must be held for 24 hours to verify pressure has not exceeded pressure limits. Acetylene plants have operating manuals that contain charts to determine acceptable pressure vs. temperature parameters.

The Rexarc Company is a company in Ohio that manufactures acetylene facilities. They may provide additional information on safely operating an acetylene plant.

If your Fire Department is not welcomed at this facility, the Department of Transportation and OSHA have Carte Blanch. Also, once the rubber meets the pavement your local Highway Patrol office may curb any vehicle and conduct an inspection. It is a very large fine (per cylinder) if over-charged cylinders are on public roadways.

Good Luck

IP PRAXAIR WATCH PRAXAIR WATCH PRAXAIR WATCH

<< Home